tooj dag

Kev siv tooj dag thiab tooj liab hnub rov qab mus rau ntau pua xyoo, thiab niaj hnub no yog siv rau hauv qee qhov kev siv thev naus laus zis tshiab thiab kev siv thaum tseem siv yog ntau cov ntawv siv xws li cov twj paj nruag, tooj dag eyelets, ornamental khoom thiab kais thiab qhov rooj kho vajtse.

Brass yog dab tsi?

Brass yog ib qho alloy ua los ntawm kev sib xyaw ntawm tooj liab thiab zinc los tsim cov ntaub ntawv nrog ntau yam kev siv engineering. Brass muaj pes tsawg leeg muab cov hlau melting point haum rau ntau daim ntawv thov, nrog rau tsim nyog rau kev koom nrog siv cov txheej txheem brazing. Lub melting point ntawm tooj dag yog qis dua tooj liab nyob ib ncig ntawm 920 ~ 970 degrees Celsius nyob ntawm seb tus nqi ntawm Zn ntxiv. Brass melting point yog qis dua tooj liab vim yog ntxiv Zn. Brass alloys tuaj yeem sib txawv hauv Zn muaj pes tsawg leeg los ntawm tsawg li 5% (feem ntau hu ua Gilding Metals) mus rau ntau dua 40% raws li siv hauv machining tooj dag. Ib lo lus uas tsis tshua siv yog tooj dag bronze, qhov twg qee qhov ntxiv ntawm tin yog siv.

Dab tsi yog tooj dag siv rau?

tooj dag muaj pes tsawg leeg thiab ntxiv zinc rau tooj liab nce lub zog thiab muab ntau yam ntxwv, uas ua rau cov tooj dag yog ntau yam khoom siv. Lawv yog siv rau lawv lub zog, corrosion kuj, tsos thiab xim, thiab yooj yim ntawm kev ua hauj lwm thiab koom. Ib theem alpha tooj dag, muaj txog li 37% Zn, yog cov ductile heev thiab yooj yim rau kev ua haujlwm txias, weld thiab braze. Lub dual theem alpha-beta brasses feem ntau yog ua haujlwm kub.

Puas muaj ntau tshaj ib qho tooj dag muaj pes tsawg leeg?

Muaj ntau ntau cov tooj dag nrog ntau qhov sib txawv thiab cov yam ntxwv tshwj xeeb rau kev siv tshwj xeeb los ntawm qib sib ntxiv ntawm zinc. Qib qis ntawm Zn ntxiv feem ntau hu ua Guilding Hlau lossis Liab Brass. Thaum cov qib siab ntawm Zn yog cov alloys xws li Cartridge Brass, Dawb Machining Brass, Naval Brass. Cov brasses tom qab no kuj muaj qhov sib ntxiv ntawm lwm cov ntsiab lus. Qhov sib ntxiv ntawm cov hlau lead rau tooj dag tau siv ntau xyoo los pab lub machinability ntawm cov khoom los ntawm inducing chip so point. Raws li qhov kev pheej hmoo thiab kev phom sij ntawm cov hlau lead tau pom tau tias nws tsis ntev los no tau hloov nrog cov khoom xws li silicon thiab bismuth kom ua tiav cov yam ntxwv zoo sib xws. Cov no tam sim no paub tias yog cov hlau lead uas tsis muaj hlau lead lossis cov hlau lead dawb.

Puas muaj lwm yam ntxiv?

Yog lawm, me me ntawm lwm yam alloying ntsiab kuj tseem yuav ntxiv rau tooj liab thiab tooj dag. Commons piv txwv yog txhuas rau tshuab-muaj peev xwm raws li tau hais los saum no, tab sis kuj arsenic rau corrosion kuj mus dezincification, tin rau lub zog thiab corrosion.

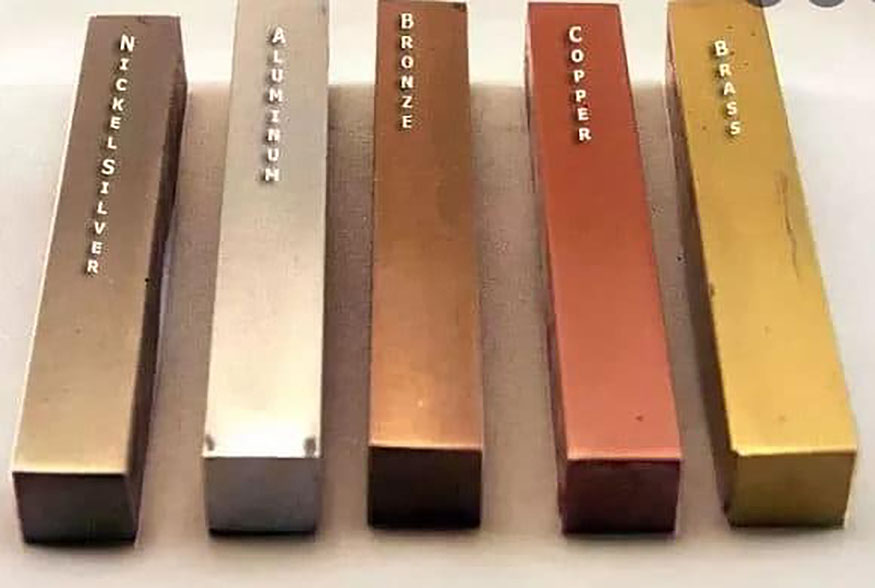

Brass Xim

Raws li cov ntsiab lus zinc nce, cov xim hloov. Qhov qis Zn alloys feem ntau zoo li tooj liab hauv cov xim, thaum lub siab zinc alloys zoo li kub lossis daj.

Tshuaj muaj pes tsawg leeg

AS2738.2 -1984 Lwm yam specifications kwv yees sib npaug

| UNS No | AS Nr | Lub Npe | BSI Nr | ISO No | JIS No | tooj liab% | Zinc% | Lead % | Lwm tus % |

| C21000 | 210 | 95/5 Gilding Hlau | - | CuZn 5 | C2100 | 94.0-96.0 Nws | ~ 5 | <0.03 | |

| C22000 | 220 | 90/10 Gilding Hlau | CZ101 | CuZn10 | C2200 | 89.0-91.0 Nws | ~ 10 | <0.05 Nws | |

| C23000 | 230 | 85/15 Gilding Hlau | CZ102 | CuZn15 | C2300 Nws | 84.0-86.0 Nws | ~ 15 | <0.05 Nws | |

| C24000 | 240 | 80/20 Gilding Hlau | CZ103 | CuZn 20 | C2400 Nws | 78.5-81.5 Nws | ~ 20 | <0.05 Nws | |

| c26130 ua | 259 | 70/30 Arsenical tooj dag | CZ126 | CuZn30As | ~ C4430 | 69.0-71.0 Nws | ~ 30 | <0.07 Nws | Arsenic 0.02-0.06 |

| C26000 | 260 | 70/30 PIB | CZ106 | CuZn30 | C2600 Nws | 68.5-71.5 Nws | ~ 30 | <0.05 Nws | |

| c26800 ua | 268 | Yellow Brass (65/35) | CZ107 | CuZn33 | c2680 ua | 64.0-68.5 Nws | ~ 33 | <0.15 Nws | |

| C27000 Nws | 270 | 65/35 Hlau tooj dag | CZ107 | CuZn35 | - | 63.0-68.5 Nws | ~ 35 | <0.10 Nws | |

| c27200 ua | 272 | 63/37 Kev Sib Tham | CZ108 | CuZn37 | c2720 ua | 62.0-65.0 Nws | ~ 37 | <0.07 Nws | |

| c35600 ua | 356 | Engraving tooj dag, 2% Lead | - | CuZn39pb 2 | c3560 ua | 59.0-64.5 Nws | ~ 39 | 2.0-3.0 Nws | |

| C37000 | 370 | Engraving tooj dag, 1% Lead | - | CuZn39pb1 | ~ C3710 | 59.0-62.0 Nws | ~ 39 | 0.9-1.4 hli | |

| C38000 | 380 | Tshooj tooj dag | CZ121 | CuZn43pb3 | - | 55.0-60.0 Nws | ~ 43 | 1.5-3.0 Nws | Aluminium 0.10-0.6 |

| c38500 ua | 385 | Dawb Txiav Brass | CZ121 | CuZn39 Pb 3 | - | 56.0-60.0 Nws | ~ 39 | 2.5-4.5 |

Cov tooj dag feem ntau siv rau lawv cov tsos

| UNS No | Lub Npe | Xim |

| C11000 Nws | ETP tooj liab | Mos liab |

| C21000 | 95/5 Gilding Hlau | Liab Xim av |

| C22000 | 90/10 Gilding Hlau | Bronze Kub |

| C23000 | 85/15 Gilding Hlau | Tan Kub |

| C26000 | 70/30 PIB | Ntsuab kub |

Gilding Hlau

C22000, 90/10 Gilding hlau, muab cov xim zoo nkauj golden nrog kev sib xyaw zoo tshaj plaws ntawm lub zog, ductility thiab corrosion kuj ntawm cov dawb Cu-Zn alloys. Nws huab cua mus rau nplua nuj xim bronze. Nws muaj peev xwm nqus tau zoo heev, thiab tiv taus pitting corrosion nyob rau hauv huab cua hnyav thiab dej ib puag ncig. Nws yog siv nyob rau hauv architectural fascias, jewellery, ornamental trim, qhov rooj kov, escutcheons, marine hardware.

Yellow tooj dag

C26000, 70/30 Brass thiab C26130, Arsenical tooj dag, muaj ductility zoo heev thiab lub zog, thiab yog cov siv tooj dag tshaj plaws. Arsenical tooj dag muaj me me ntxiv ntawm arsenic, uas zoo heev txhim kho corrosion kuj nyob rau hauv dej, tab sis yog lwm yam zoo tib yam. Cov hlau no muaj qhov txawv xim daj daj uas feem ntau cuam tshuam nrog tooj dag. Lawv muaj qhov zoo tshaj plaws ua ke ntawm lub zog thiab ductility nyob rau hauv Cu-Zn alloys, ua ke nrog zoo corrosion kuj. C26000 yog siv rau architecture, kos thiab spun ntim thiab cov duab, hluav taws xob terminals thiab connectors, qhov rooj tuav, thiab cov khoom siv kav dej. C26130 yog siv rau cov raj thiab fittings hauv kev sib cuag nrog dej, suav nrog cov dej haus.

C26800, Yellow tooj dag, yog ib theem alpha tooj dag nrog cov ntsiab lus qis tshaj ntawm tooj liab. Nws yog siv qhov twg nws cov khoom sib sib zog nqus nqus thiab tus nqi qis muab qhov zoo dua. Thaum welded hais ntawm beta theem yuav tsim, txo ductility thiab corrosion kuj.

Brass nrog lwm yam

C35600 thiab C37000, Engraving tooj dag, yog 60/40 alpha-beta brasses nrog ntau theem ntawm cov hlau lead ntxiv kom muab cov yam ntxwv dawb machining. Lawv yog dav siv rau engraved daim hlau thiab plaques, builders hardware, gears. Lawv yuav tsum tsis txhob siv rau cov kua qaub-etched, uas yuav tsum tau siv ib-theem alpha tooj dag.

C38000, Section tooj dag, yog ib qho yooj yim extrudable leaded alpha/beta tooj dag nrog ib tug me me txhuas ntxiv, uas muab ib tug kaj golden xim. Cov hlau lead muab cov yam ntxwv ntawm kev txiav dawb. C38000 muaj nyob rau hauv extruded rods, raws, flats thiab ces kaum, uas feem ntau yog siv nyob rau hauv builders kho vajtse.

C38500, txiav tooj dag, yog ib daim ntawv zoo ntawm 60/40 tooj dag, nrog cov yam ntxwv zoo dawb-txiav. Nws yog siv nyob rau hauv loj zus tau tej cov tooj dag Cheebtsam qhov twg siab tshaj plaws tso zis ntau thiab ntev lub cuab tam lub neej yuav tsum tau, thiab qhov twg tsis muaj ntxiv txias txias tom qab machining yuav tsum tau.

Cov khoom siv tooj dag

● Daim ntawv khoom

● Rolled ca khoom

● Wrought rods, tuav & seem

● Forging Tshuag & forgings

● Seamless raj rau cua sov exchangers

● Seamless raj rau cua txias & tub yees

● Seamless raj rau engineering lub hom phiaj

● Hlau rau engineering lub hom phiaj

● Hlau rau lub hom phiaj hluav taws xob

Jindalai Steel Group muaj ntau yam khoom siv tooj dag hauv qhov ntau thiab tsawg kom tau raws li qhov xav tau ntawm txhua qhov haujlwm. Peb kuj lees txais cov qauv kev cai, qhov ntau thiab tsawg, cov duab, thiab xim. Xa koj cov lus nug thiab peb yuav zoo siab los sab laj koj tus kws tshaj lij.

HOTLINE:+86 18864971774WECHAT: +86 18864971774WhatsApp:https://wa.me/8618864971774

EMAIL:jindalaisteel@gmail.com sales@jindalaisteelgroup.com WEBSITE:www.jindalaisteel.com

Post lub sij hawm: Dec-19-2022