1. Kauj Ruam Ib: Smelting

Aluminium yog tsim los siv electrolysis ntawm kev lag luam nplai thiab aluminium smelters xav tau ntau lub zog kom khiav tau zoo. Smelters feem ntau nyob ib sab ntawm cov chaw tsim hluav taws xob loj vim lawv xav tau lub zog. Ib qho kev nce nqi ntawm lub hwj chim, lossis tus nqi ntawm lub zog yuav tsum tau ua kom zoo dua aluminium rau qib siab dua, ua rau cov nqi ntawm aluminium coils. Tsis tas li ntawd, cov txhuas uas tau yaj tau sib cais thiab mus rau qhov chaw sau. Cov txheej txheem no tseem muaj cov kev xav tau ntawm lub zog loj, uas cuam tshuam rau cov nqi lag luam txhuas thiab.

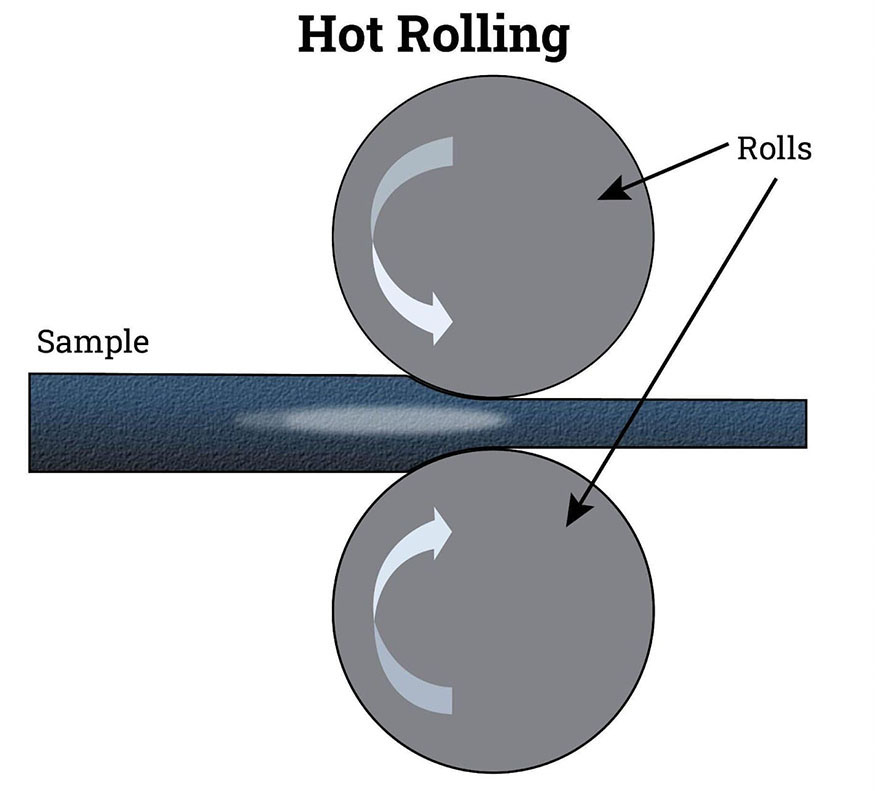

2. Kauj Ruam Ob: Kub Rolling

Kub dov yog ib qho ntawm feem ntau siv txoj hauv kev los ua nyias ib qho txhuas slab. Nyob rau hauv kub dov, hlau yog rhuab saum lub point ntawm recrystallization kom deform thiab ntxiv rau nws. Tom qab ntawd, cov khoom siv hlau no tau dhau los ntawm ib lossis ntau khub ntawm yob. Qhov no yog ua los txo cov tuab, ua kom tuab tuab, thiab ua tiav cov khoom siv kho kom zoo. Aluminium coil yog tsim los ntawm kev ua cov ntawv ntawm 1700 degrees Fahrenheit.

Txoj kev no tuaj yeem tsim cov duab nrog qhov tsim nyog geometrical tsis thiab cov yam ntxwv ntawm cov khoom thaum khaws cov hlau ntim tas li. Cov haujlwm no yog qhov tseem ceeb hauv kev tsim cov khoom ib nrab thiab tiav, xws li cov phaj thiab cov ntawv. Txawm li cas los xij, cov khoom tiav dov txawv ntawm cov khoom siv txias txias, uas yuav tau piav qhia hauv qab no, nyob rau hauv uas lawv tsis tshua muaj tuab tuab vim tias cov khib nyiab me me ntawm qhov chaw.

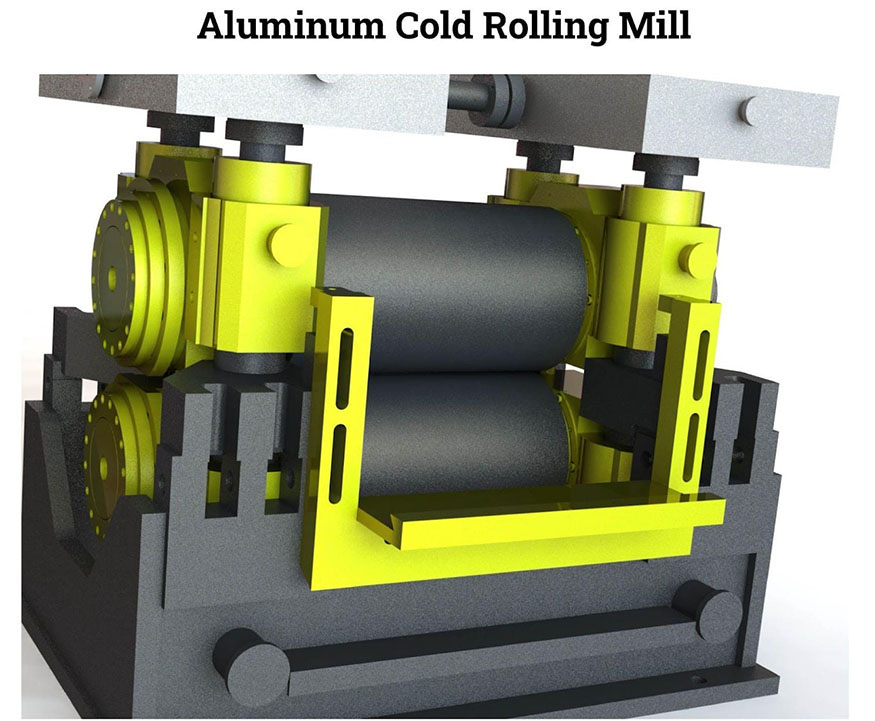

3. Kauj Ruam Peb: Txias Rolling

Txias dov ntawm cov hlau strips yog ib qho chaw tshwj xeeb ntawm kev ua haujlwm hlau. Cov txheej txheem ntawm "txias dov" suav nrog muab cov txhuas los ntawm cov chais ntawm qhov kub thiab txias qis dua nws qhov kub ntawm recrystallization. Squeezing thiab compressing cov hlau tsub kom nws yield zog thiab hardness. Txias dov tshwm sim ntawm qhov chaw ua hauj lwm-hardening kub (qhov kub hauv qab ntawm cov khoom siv recrystallization kub), thiab kub dov tshwm sim saum qhov ua hauj lwm hardening kub - qhov no yog qhov txawv ntawm kub dov thiab txias dov.

Ntau qhov kev lag luam siv cov txheej txheem kev kho hlau hu ua txias dov los tsim cov sawb thiab cov ntawv hlau nrog qhov kev ntsuas zaum kawg. Cov yob feem ntau ua kom sov los pab cov txhuas ua haujlwm ntau dua, thiab cov roj nplua nyeem yog siv los tiv thaiv cov txhuas sawb los ntawm kev lo rau cov yob. Rau kev ua haujlwm zoo-tuning, cov rolls txav thiab cua sov tuaj yeem hloov pauv. Ib qho txhuas sawb, uas twb dhau los ua kub dov, thiab lwm yam txheej txheem, suav nrog kev tu thiab kho, yog txias rau chav sov ua ntej muab tso rau hauv ib qho txias zeb dov kab hauv kev lag luam txhuas. Aluminium yog ntxuav los ntawm rinsing nws nrog xab npum thiab qhov kev kho mob no ua rau cov aluminium coil nyuaj txaus los tiv thaiv txias dov.

Tom qab cov txheej txheem npaj tau hais tseg lawm, cov strips tau rov qab hla dhau los ntawm cov yob, nce zuj zus poob tuab. Cov hlau lub lattice dav hlau raug cuam tshuam thiab tawm-tawm thoob plaws hauv cov txheej txheem, uas ua rau muaj kev nyuaj, muaj zog dua cov khoom kawg. Txias dov yog ib txoj hauv kev nrov tshaj plaws rau hardening aluminium vim nws txo cov thickness ntawm txhuas raws li nws yog crushed thiab thawb los ntawm rollers. Cov txheej txheem txias dov tuaj yeem txo qis aluminium coil lub thickness txog li 0.15 hli.

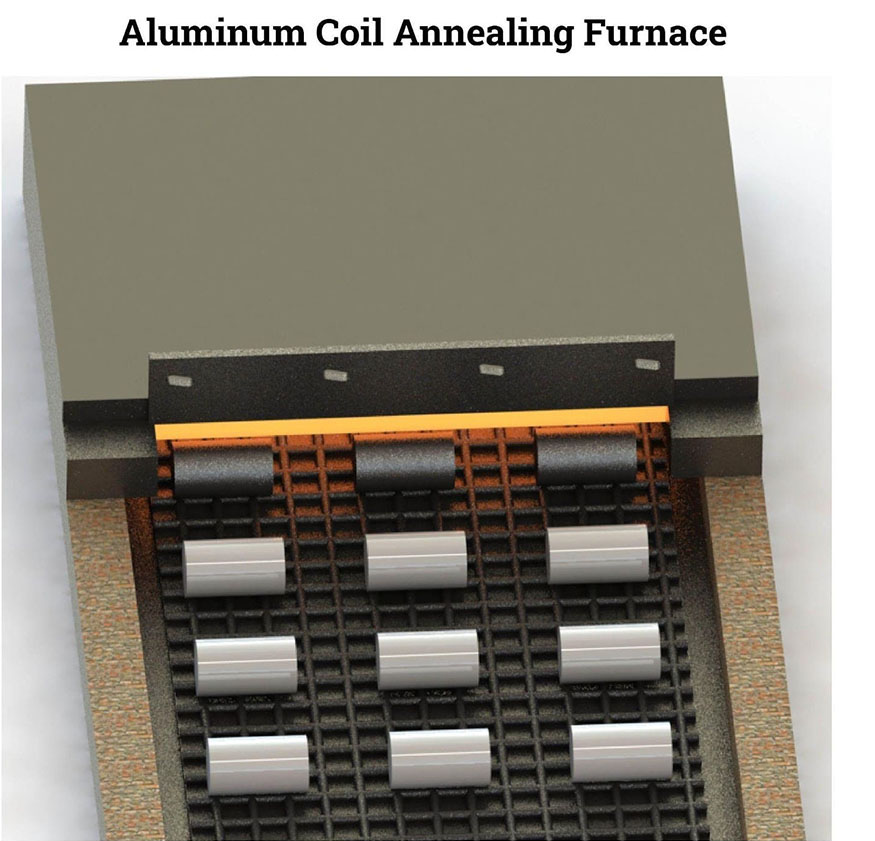

4. Kauj Ruam 4: Nthuav tawm

Cov txheej txheem annealing yog kev kho cua sov siv feem ntau los ua kom cov khoom siv tau yooj yim dua thiab tsis nruj. Qhov txo qis hauv dislocations nyob rau hauv cov qauv siv lead ua ntawm cov khoom raug annealed ua rau qhov kev hloov ntawm hardness thiab yooj. Txhawm rau kom tsis txhob nkig tsis ua haujlwm lossis ua kom cov khoom siv tau zoo dua rau kev ua haujlwm tom qab, kev sib tsoo yog nquag ua tom qab cov khoom tau dhau los ua cov txheej txheem ua haujlwm hnyav lossis txias.

Los ntawm kev kho kom zoo dua cov qauv crystalline grain, annealing restores plam dav hlau thiab enables ntxiv shaping ntawm ib feem tsis muaj zog ntau dhau. Ib qho kev ua haujlwm-hardened aluminium alloy yuav tsum tau ua kom sov rau qhov kub ntawm 570 ° F thiab 770 ° F rau lub sijhawm ua ntej, txij li peb caug feeb mus rau peb teev. Qhov luaj li cas ntawm qhov raug annealed thiab alloy nws yog ua los ntawm kev txiav txim siab qhov kub thiab txias thiab lub sij hawm xav tau, feem.

Annealing kuj stabilizes ib feem ntawm qhov ntev, tshem tawm cov teeb meem los ntawm cov kab mob sab hauv, thiab txo cov kev ntxhov siab sab hauv uas yuav tshwm sim, ib feem, thaum cov txheej txheem xws li txias forging lossis casting. Tsis tas li ntawd, aluminium alloys uas tsis muaj cua sov tuaj yeem kho tau zoo. Yog li ntawd, nws feem ntau siv rau cam khwb cia, extruded, los yog forged aluminium qhov chaw.

Cov khoom muaj peev xwm tsim tau zoo dua los ntawm kev sib tsoo. Nias los yog dabtsi yog khoov nyuaj, nkig cov ntaub ntawv yuav nyuaj yam tsis ua rau puas. Annealing pab tshem tawm qhov kev pheej hmoo no. Tsis tas li ntawd, annealing tuaj yeem ua rau kom muaj peev xwm. Lub brittleness heev ntawm cov khoom yuav ua rau cov cuab yeej siv ntau dhau. Los ntawm annealing, cov khoom hardness tuaj yeem txo qis, uas tuaj yeem txo cov cuab yeej hnav. Txhua qhov kev ntxhov siab ntxiv raug tshem tawm los ntawm kev sib tsoo. Feem ntau nws yog qhov zoo tshaj plaws los txo cov kev ntxhov siab nyob qhov twg los xij vim tias lawv tuaj yeem ua rau tawg thiab lwm yam teeb meem.

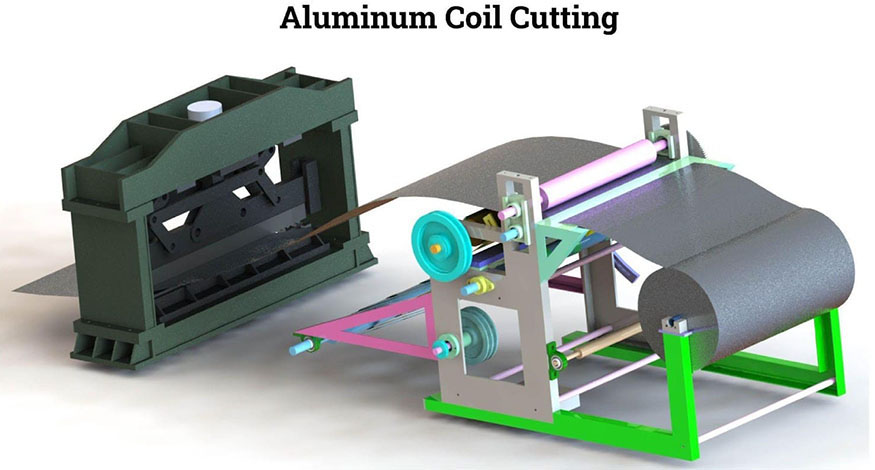

5. Kauj Ruam 5: Txiav thiab txiav

Aluminium coils tuaj yeem tsim nyob rau hauv ib lub voj voog ntev heev. Txhawm rau ntim cov kauj rau hauv cov yob me me, txawm li cas los xij, lawv yuav tsum tau txiav. Txhawm rau ua qhov haujlwm no, aluminium yob yog khiav los ntawm cov cuab yeej slitting qhov twg cov hniav ntse ntse ua kom raug txiav. Yuav tsum muaj ntau lub zog los ua qhov haujlwm no. Slitters faib cov yob rau hauv me me thaum lub zog siv ntau tshaj qhov txhuas lub zog tensile.

Txhawm rau pib txheej txheem slitting, aluminium yog muab tso rau hauv lub uncoiler. Tom qab ntawd, nws yog dhau los ntawm ib txheej ntawm cov riam rotary. Cov hniav yog positioned kom tau qhov zoo tshaj plaws slit ntug, xav txog qhov xav tau dav thiab clearance. Txhawm rau coj cov khoom slit mus rau lub recoiler, cov khoom yog tom qab noj los ntawm cov khoom sib cais. Tom qab ntawd cov aluminium yog bundled thiab qhwv rau hauv ib lub kauj los npaj rau shipping.

Jindalai Steel Group yog Lub Tuam Txhab Uas Txhuas Txhuas thiab Chaw Muag Khoom ntawm aluminium coil / ntawv / phaj / sawb / yeeb nkab / ntawv ci. Peb muaj cov neeg siv khoom los ntawm Philippines, Thane, Mexico, Qaib Cov Txwv, Pakistan, Oman, Ixayees, Egypt, Arab, Nyab Laj, Myanmar, Is Nrias teb thiab lwm yam. Xa koj cov lus nug thiab peb yuav zoo siab los sab laj nrog koj.

HOTLINE:+86 18864971774WECHAT: +86 18864971774WhatsApp:https://wa.me/8618864971774

EMAIL:jindalaisteel@gmail.com sales@jindalaisteelgroup.com WEBSITE:www.jindalaisteel.com

Post lub sij hawm: Dec-19-2022