Brass yog cov hlau alloy uas ua los ntawm tooj liab thiab zinc. Vim yog tooj dag cov khoom tshwj xeeb, uas kuv yuav nkag mus rau hauv cov ncauj lus kom ntxaws hauv qab no, nws yog ib qho ntawm cov khoom siv dav tshaj plaws. Vim nws cov versatility, muaj seemingly kawg industries thiab cov khoom siv ntawm no alloy.

1. UNIQUE PROPERTIES NTAWM BRASS

Lub proportions ntawm zinc thiab tooj liab nyob rau hauv tooj dag yuav varied, tsim ib tug ntau yam ntawm tooj dag nrog txawv zog. Vim lub variation nyob rau hauv lub alloy, tooj dag zog tsis universal. Tab sis, cov alloys paub tias yog yooj yim tsim (xws li machinability) thiab tuav lub zog siab tom qab tsim. Tag nrho cov tooj dag tau paub tias yog ductile-variations nrog qis zinc cov ntsiab lus yog ntau ductile thiab variations nrog zinc cov ntsiab lus ntau dua li.

Zoo ib yam li tooj liab, tooj dag yog qhov chaw yug me nyuam tsis zoo rau cov kab mob. Qhov kev ua tau zoo no ua rau nws yog cov khoom siv zoo tshaj plaws rau cov khoom siv hauv chav dej thiab cov qhov rooj, nrog rau kev siv tshuaj kho mob.

1. COMMON SIV RAU BRASS

Brass yog dav siv nyob rau hauv daim ntaub ntawv uas yog kho kom zoo nkauj thiab mechanical. Vim nws cov khoom tshwj xeeb, uas suav nrog kev tiv thaiv corrosion, kev siv ntau rau tooj dag suav nrog cov ntawv thov uas yuav tsum muaj kev sib txhuam qis. Cov ntawv thov no tuaj yeem suav nrog fittings (fasteners thiab connectors), cov cuab yeej, cov khoom siv, thiab cov mos txwv.

2. DAIM NTAWV CEEB TOOM

Tshaj li nws cov khoom siv tshuaj tua kab mob, tooj dag tus nqi zoo nkauj ua rau nws muaj kev xaiv nrov rau cov ntaub ntawv kho kom zoo nkauj. Nws cov xim tuaj yeem ua tau los ntawm lub teeb kub thiab nyiaj txhua txoj kev mus rau yuav luag liab.

Cov tshuab ntxuav tais diav hauv tsev thiab cov khoom siv teeb pom kev zoo feem ntau yog ua los ntawm tooj dag, vim tias lawv ob leeg pom kev thiab cov kab mob resistant.

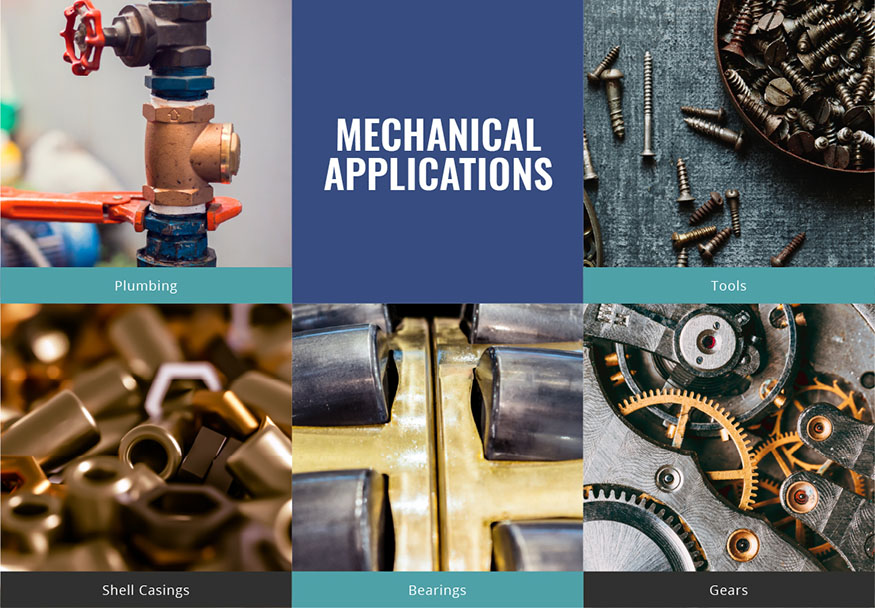

3. MECHANICAL APPLICATIONS

Los ntawm lub plhaub casings rau M-16 phom phom mus rau txhua hnub siv bearings thiab iav, tooj dag yog dav siv rau kev siv tshuab. Cov cuab yeej ua los ntawm tooj dag paub tias muaj lub neej ntev thiab txo qis kev xav tau kev ua kom zoo.

4. MUSICAL INSTRUMENTS

Yog tias koj puas tau koom nrog hauv kev ua yeeb yam, kev ua yeeb yam, lossis tej zaum txawm tias muaj suab paj nruag, koj yuav paub zoo txog cov tooj dag nyob ib puag ncig koj. Trumpets, Fabkis horns, trombones, baritones, thiab tubas yog qee yam khoom siv tooj dag nrov tshaj plaws.

5. BRASS CARRIED NTAWM JINDALAI

Jindalai Steel Group muaj ntau yam khoom siv tooj dag hauv qhov ntau thiab tsawg kom tau raws li qhov xav tau ntawm txhua qhov haujlwm. Peb Tshuag ASTM tooj dag, uas muaj qhov siab tshaj plaws ductility ntawm txhua yam khoom siv tooj dag daj. Nws yog resistant rau weathering thiab yog zoo tagnrho rau siv nyob rau hauv corrosive ib puag ncig.

Peb khaws cov ntawv tooj dag thiab cov coils hauv thickness ntawm 0.05 mus rau 50mm, thiab nyob rau hauv annealed, quarter nyuaj, ib nrab nyuaj, thiab tag nrho cov tempers nyuaj. Lwm cov tempers thiab alloys kuj muaj.

HOTLINE:+86 18864971774WECHAT: +86 18864971774WhatsApp:https://wa.me/8618864971774

EMAIL:jindalaisteel@gmail.com sales@jindalaisteelgroup.com WEBSITE:www.jindalaisteel.com

Post lub sij hawm: Dec-19-2022