Cov ntsiab lus ntawm Chrome Moly Phaj

Chrome moly phaj raws li ASTM A387 nyob rau hauv cov qib serveral uas muaj cov ntsiab lus sib txawv raws li hauv qab no, cov qib siv feem ntau yog Gr 11, 22, 5, 9 thiab 91.

Tsuas yog 21L, 22L thiab 91, txhua qib muaj nyob rau hauv ob chav kawm ntawm qib tensile zog raws li tau hais tseg hauv cov lus xav tau tensile. Qib 21L thiab 22L tsuas muaj hoob 1 xwb, thiab Qib 91 tsuas muaj Class2 xwb.

| Qib | Nominal Chromium Cov ntsiab lus,% | Nominal Molybdenum Cov ntsiab lus,% |

| 2 | 0.50 ib | 0.50 ib |

| 12 | 1.00 Nws | 0.50 ib |

| 11 | 1.25 | 0.50 ib |

| 22, 22 l | 2.25 | 1.00 Nws |

| 21, 21 l | 3.00 Nws | 1.00 Nws |

| 5 | 5.00 Nws | 0.50 ib |

| 9 | 9.00 Nws | 1.00 Nws |

| 91 | 9.00 Nws | 1.00 Nws |

ASTM A387 Alloy Steel Phaj ASTM

A20 / A20M: Cov kev cai dav dav rau cov phaj siab.

A370: Test specification rau txhua yam khoom ntawm hlau

A435 / A435M: Rau ncaj-beam ultrasonic kuaj ntawm steel daim hlau.

A577 / A577M: Rau ultrasonic lub kaum sab xis kuaj ntawm cov hlau phaj.

A578 / A578M: Rau txoj kab ncaj nraim UT kev tshuaj xyuas ntawm cov hlau yob hauv cov ntawv tshwj xeeb.

A1017 / A1017M: Specification rau siab vessle daim hlau ntawm hlau alloy, chromium-molybdenum-tungsten.

AWS Specification

A5.5 / A5.5M: Tsawg alloy steel electrodes rau shield hlau arc vuam.

A5.23 / A5.23M: Tsawg alloy steel electrodes rau fulxes rau submerged arc vuam.

A5.28 / A5.28M: Rau roj shielded arc vuam.

A5.29 / A5.29M: Rau flux cored arc vuam.

Kev kho cua sov rau A387 Chrom Moly Alloy Steel Phaj

Chrome moly alloy steel phaj nyob rau hauv ASTM A387 yuav tsum raug tua hlau, nrog thermally kho los ntawm annealing, normarlizing thiab tempering. Los yog nyob rau hauv cov ntaub ntawv pom zoo los ntawm buyer, ceev ceev txias los ntawm lub austenitizing kub los ntawm huab cua blasting los yog kua quenching, ua raws li los ntawm tempering, yam tsawg kawg nkaus tempering kub yuav tsum tau raws li hauv qab no cov lus:

| Qib | Kub, ° F [° C] |

| 2, 12 thiab 11 | 1150 [620] ib. |

| 22, 22L, 21, 21L thiab 9 | 1250 [675] |

| 5 | 1300 [705] |

Qib 91 alloy steel daim hlau yuav tsum tau kho cua sov los ntawm normalizing thiab tempering los yog ceev cua txias los ntawm huab cua blasting los yog kua quenching, ua raws li tempering. Qib 91 daim hlau yuav tsum tau austenitized ntawm 1900 txog 1975 ° F [1040 txog 1080 ° C] thiab yuav tsum tau tempered ntawm 1350 txog 1470 ° F [730 txog 800 ° C]

Qib 5, 9, 21, 21L, 22, 22L, thiab 91 daim hlau txiav txim yam tsis muaj kev kho cua sov los ntawm cov lus saum toj no, yuav tsum ua kom tiav nyob rau hauv qhov kev ntxhov siab los yog kev mob annealed.

Daim duab nthuav dav

-

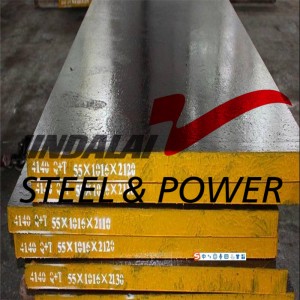

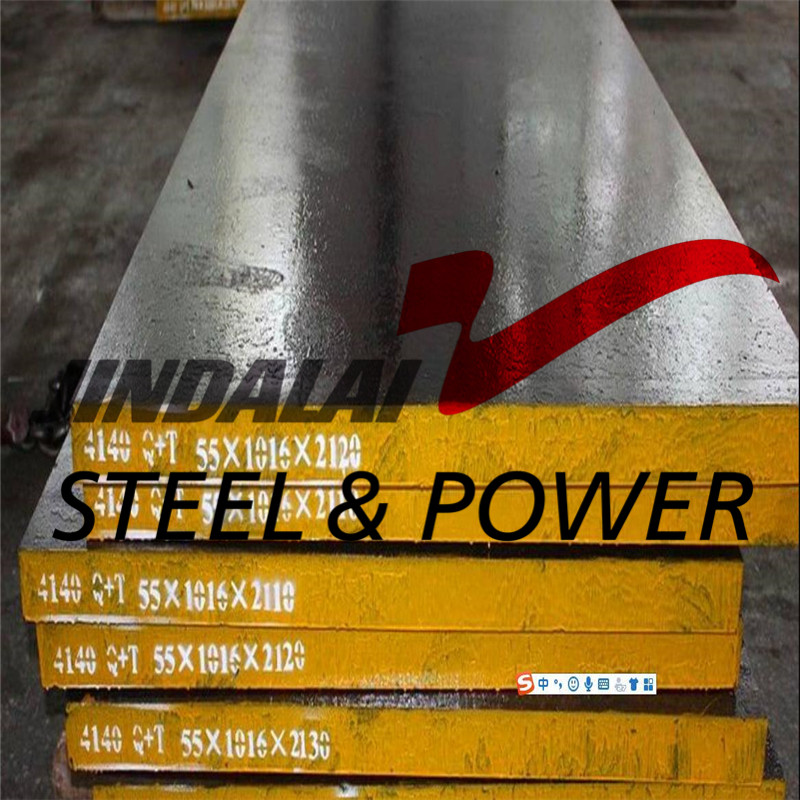

4140 Alloy Steel Phaj

-

Nickel 200/201 Nickel Alloy Phaj

-

Nickel Alloy Phaj

-

ASTM A36 Hlau Phaj

-

Checkered Steel Phaj

-

AR400 Steel Phaj

-

Abrasion Resistant Steel Phaj

-

A 516 Qib 60 Vessel Steel Phaj

-

Boiler Steel Phaj

-

Pipeline Steel Phaj

-

S235JR Carbon Steel Phaj / MS Phaj

-

S355 Steel Phaj

-

Shipbuilding Steel Phaj

-

SA516 GR 70 Siab Vessel Steel Phaj

-

ST37 Steel Phaj / Carbon Steel Phaj