Qib ntawm High Steel Carbon Phaj

| ASTM A283 / A283M ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283 / ASTM A283) thiab ASTM A283 | ASTM A573 / ASTM A573M / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573 / ASTM A573) thiab ASTM A573 | ASME SA36/SA36M |

| ASME SA283/SA283M | ASME SA573/SA573M | TS EN 10025-2 |

| TS EN 10025-3 | TS EN 10025-4 | TS EN 10025-6 |

| JIS G3106 | TIAB SA 17100 | TIAB SA 17102 |

| GB / T16270 | GB / T700 | GB/T1591 |

Siv A36 daim ntawv thov ua piv txwv

Daim ntawv thov ntawm ASTM A36 Carbon Structural Steel Phaj

| Machinery Parts | Ncej | Fixtures | Bearing Phaj | Tank | Bins | Bearing Phaj | Forgings |

| Plua Plav | Gears | Cams | Sprockets | Jigs | Nplhaib | Cov qauv | Fixtures |

| ASTM A36 Steel Phaj Fabrication Options | |||||||

| Txias Khoov | Mild Kub txoj kev | xuas nrig ntaus | Tshuab dhos | Vuam | Txias Khoov | Mild Kub txoj kev | xuas nrig ntaus |

Tshuaj muaj pes tsawg leeg ntawm A36

| ASTM A36 Kub Rolled Steel Phaj | Tshuaj Compostion | |

| Element | cov ntsiab lus | |

| Carbon, C | 0.25 - 0.290% | |

| tooj, Cu | 0.20% | |

| Hlau, Fe | 98.0% | |

| Manganese, Mn | 1.03% | |

| Phosphorus, P | 0.040% | |

| Silicon, Sib | 0.280% | |

| Sulfur, S | 0.050% | |

Lub cev khoom ntawm A36

| Lub cev khoom | Metric | Imperial |

| Qhov ntom | 7,85g 3 | 0.284 lb/in 3 |

Mechanical Property ntawm A36

| ASTM A36 Kub Rolled Steel Phaj | ||

| Mechanical Properties | Metric | Imperial |

| Tensile Strength, Qhov kawg | 400-550 MPa | 58000-79800 psi |

| Tensile zog, tawm los | 250 MPa | 36 300 psi |

| Elongation ntawm Break (hauv 200 mm) | 20.0% | 20.0% |

| Elongation ntawm Break (hauv 50 mm) | 23.0% | 23.0% |

| Modulus ntawm Elasticity | 200 GPa | 29 000 ksg |

| Bulk Modulus (tseem ceeb rau steel) | 140 GPa | 20 300 TZS |

| Poissons Ratio | 0.260 Nws | 0.260 Nws |

| Shear Modulus | 7 9.3 gvp | 11 500 ksg |

Cov pa roj carbon steel yog cov hlau uas muaj hlau thiab carbon. Ob peb lwm cov ntsiab lus tau tso cai nyob rau hauv cov pa roj carbon steel, nrog tsawg feem pua. Cov ntsiab lus no yog manganese, nrog 1.65% siab tshaj plaws, silicon, nrog 0.60% siab tshaj plaws, thiab tooj liab, nrog 0.60% siab tshaj. Lwm cov ntsiab lus tuaj yeem muaj nyob rau hauv qhov me me dhau los cuam tshuam rau nws cov khoom.

Muaj plaub hom carbon hlau

Raws li tus nqi ntawm carbon tam sim no nyob rau hauv lub alloy. Cov pa roj carbon tsawg yog softer thiab tsim tau yooj yim dua, thiab cov hlau uas muaj cov pa roj carbon ntau dua yog qhov nyuaj thiab muaj zog dua, tab sis tsawg dua, thiab lawv nyuaj rau tshuab thiab vuam. Hauv qab no yog cov khoom ntawm cov qib ntawm carbon steel peb muab:

● Tsawg Carbon Steel-Composition ntawm 0.05%-0.25% carbon thiab mus txog 0.4% manganese. Kuj tseem hu ua cov hlau me me, nws yog cov khoom siv qis qis uas yooj yim rau cov duab. Txawm hais tias tsis nyuaj npaum li cov pa roj carbon ntau dua, lub tsheb burizing tuaj yeem ua rau nws qhov tawv tawv.

● Medium Carbon Steel - Cov ntsiab lus ntawm 0.29% -0.54% carbon, nrog 0.60% -1.65% manganese. Cov pa roj carbon monoxide nruab nrab yog ductile thiab muaj zog, nrog rau kev hnav ntev.

● High Carbon Steel – Muaj 0.55%-0.95% carbon, nrog 0.30%-0.90% manganese. Nws muaj zog heev thiab tuav lub cim xeeb zoo, ua rau nws zoo tagnrho rau cov springs thiab hlau.

● High Carbon Steel - Cov ntsiab lus ntawm 0.96% -2.1% carbon. Nws cov ntsiab lus carbon siab ua rau nws muaj zog heev. Vim nws qhov brittleness, qib no yuav tsum tau tuav tshwj xeeb.

Daim duab nthuav dav

-

A36 Kub Rolled Steel Phaj Hoobkas

-

Q345, A36 SS400 Steel Chev

-

ASTM A36 Hlau Phaj

-

ASTM A653 Z275 Galvanized Steel Chev Tuam Tshoj Hoobkas

-

S355 Steel Phaj

-

S355G2 Offshore Steel Phaj

-

S355J2W Corten Phaj Weathering Steel Phaj

-

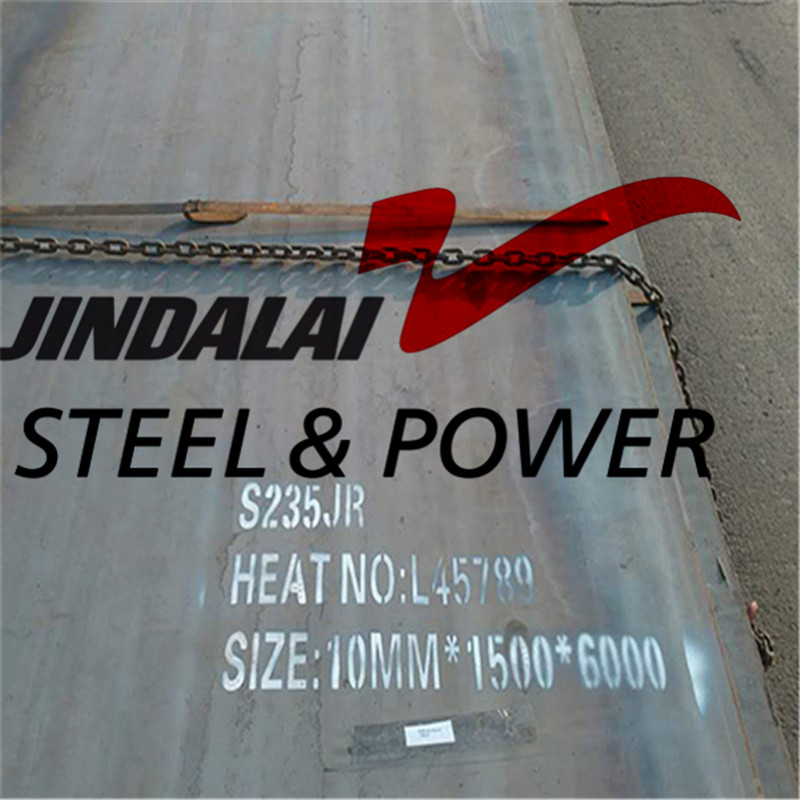

S235JR Carbon Steel Phaj / MS Phaj

-

SS400 Q235 ST37 Kub Rolled Steel Chev

-

Checkered Steel Phaj

-

Kub Rolled Galvanized Checkered Steel Phaj

-

MILD STEEL (MS) CHECKERED Plate

-

Kub Rolled Checkered Chev / Ms Checkered Coils / HRC